Fatigue analysis is essential when a product experiences cyclic loads (vibration, motion, pressure pulsation, thermal cycling). It answers a different question than static checks: How long will it last under real operating conditions?

Fatigue failures often originate at stress concentrations and grow over time under repeated loading.

Fatigue failures are often invisible in static analysis

A component can pass static strength checks with a comfortable safety margin and still fail prematurely in service. This happens when the product experiences repeated or cyclic loading, even at stress levels well below yield.

Static analysis asks: Will it survive one load case?

Fatigue analysis asks: Will it survive millions of cycles?

Why fatigue matters to decision makers

Fatigue is a business risk because it is easy to miss early—and costly to fix late. When fatigue is not addressed, teams often discover issues during validation testing or after launch, when changes are disruptive.

What fatigue analysis prevents

- Unexpected field failures that lead to warranty claims or recalls

- Overdesign driven by fear instead of evidence

- Late-stage redesign loops and schedule slips

- Maintenance surprises due to unclear service life

What decision makers gain

- Durability confidence tied to real load environments

- Better cost/weight tradeoffs with traceable justification

- Risk-based prioritization (fix the real hotspots first)

- Cleaner sign-off documentation for stakeholders

Typical scenarios where fatigue is a real risk

Fatigue analysis is especially important when products are exposed to:

Vibration & cycling

- Motor/engine vibration and resonance bands

- Rotating or reciprocating machinery

- Repeated clamp load variation (fasteners, joints)

Thermal & pressure cycling

- Thermal expansion/contraction cycles

- Pressure pulsation (pumps, valves, vessels)

- Startup/shutdown operating cycles

Common examples include brackets, mounts, housings, fasteners, electronic enclosures, and structural components in industrial, automotive, aerospace, and consumer products.

What fatigue analysis needs as inputs

Fatigue assessment typically builds on results from static or dynamic simulation and combines them with material data and realistic load histories.

Technical inputs

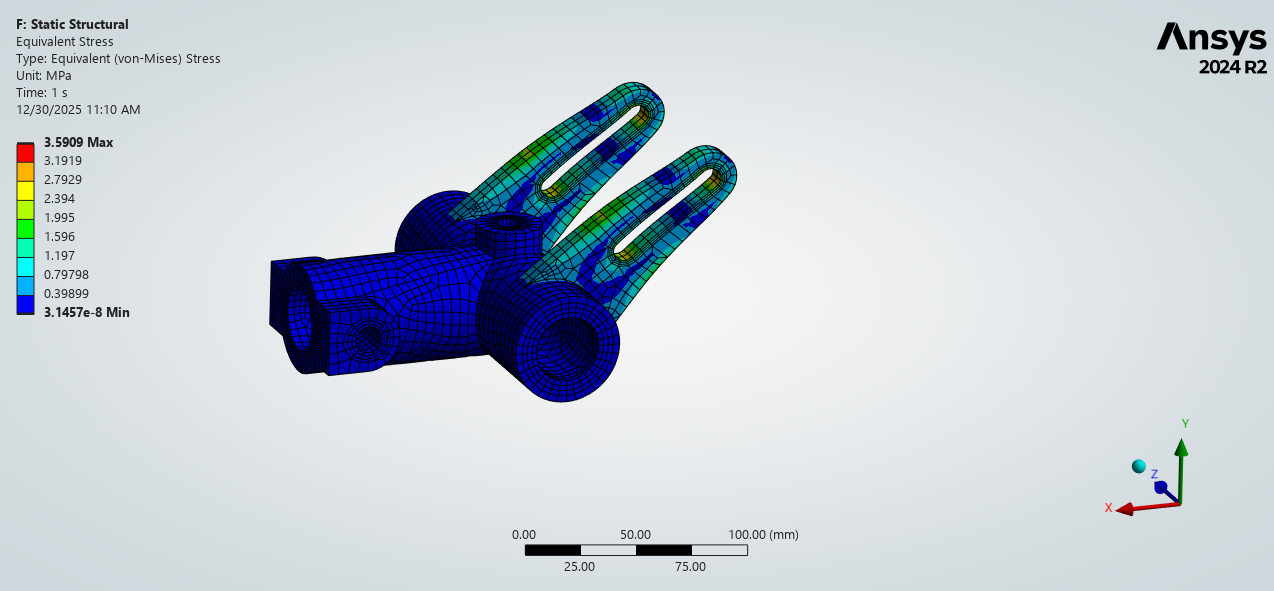

- Stress results (static, harmonic, random, transient)

- Material fatigue data (S–N or ε–N, mean stress correction)

- Cycle definition (amplitude, mean load, frequency content)

- Boundary conditions that reflect real fixtures and joints

Typical outputs

- Hotspot ranking (critical locations to fix first)

- Estimated life (cycles or time)

- Safety factor / damage maps

- Design changes to increase life with minimal weight/cost

Fatigue analysis as a risk-management tool

From a business perspective, fatigue analysis is less about predicting an exact failure day and more about reducing uncertainty. It helps teams identify critical hotspots, evaluate design alternatives, and make informed tradeoffs between durability, weight, and cost.

Done early, fatigue analysis reduces the likelihood of late-stage redesign and post-launch failures— while avoiding unnecessary overbuild.

Planning for fatigue early prevents costly surprises later.

Tetra Elements supports teams with fatigue workflows based on real load environments—fast, defensible, and NDA-friendly.

Note: Fatigue analysis typically builds on static or dynamic FEA results and uses material S–N data (or strain-life) to estimate damage accumulation and service life. The right method depends on loading type, mean stress, and cycle definition.