FEA, CFD & Multiphysics Simulation Consulting

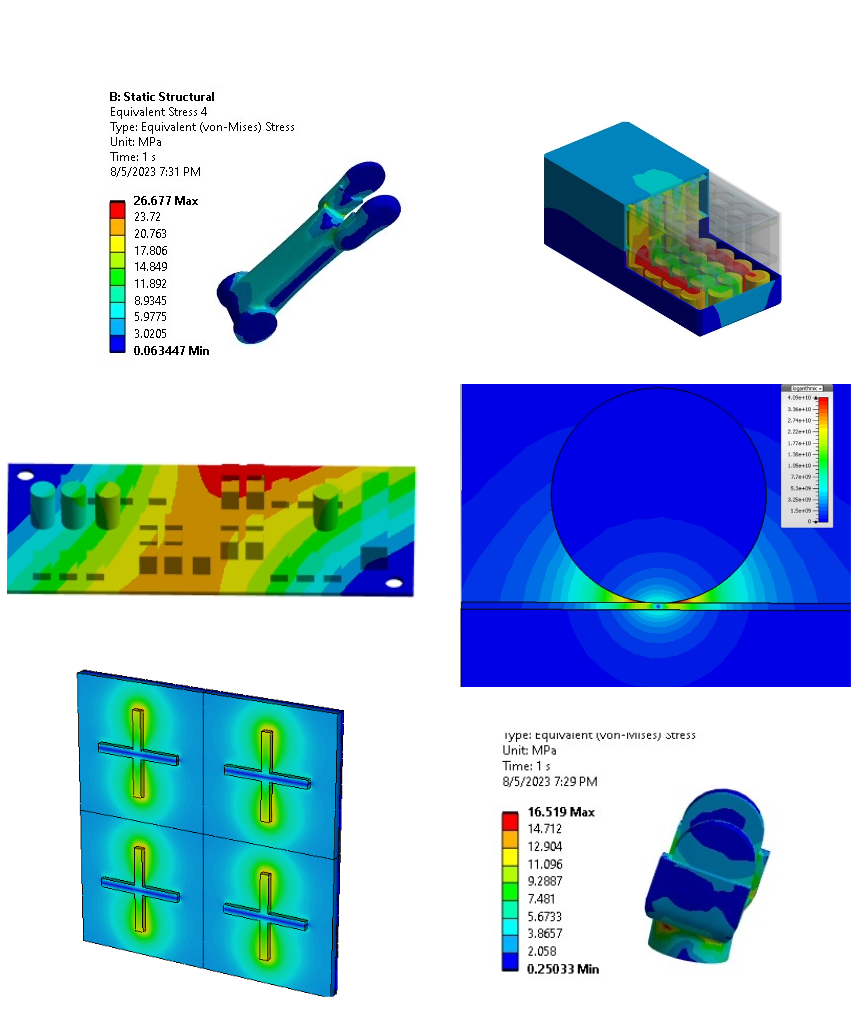

We help engineering teams reduce risk and accelerate design decisions with reliable, simulation-driven insights—structural, thermal, dynamics, CFD, EM, and optics.

Industries served

We support simulation needs across a range of product and infrastructure domains.

Free consultation

Book a complimentary 30-minute consultation. We’ll review your goals, constraints, and simulation approach— and recommend a clear path forward.

- Static & structural analysis

- Stress/strain and deformation

- Dynamics, impact & drop tests

- Modal & vibration

- Thermal & electro-thermal

- Fatigue and durability

- CFD & heat transfer

- EM simulation & antenna design

- Optics & ray tracing

- Custom multiphysics studies

* We are prepared to sign an NDA according to your specifications to safeguard your valuable assets.

How we work

Intake & scoping

We align on objectives, load cases, constraints, and deliverables. You get a clear plan and timeline.

- Requirements + assumptions

- Materials, BCs, load cases

- Deliverable definition

Model & simulation

We build the model, verify setup, and iterate efficiently to converge on trustworthy results.

- Mesh & solver setup

- Validation checks

- Optimization iterations

Results & handoff

You receive clear plots, interpretations, and design recommendations—ready for decisions.

- Report + visuals

- Design recommendations

- Optional follow-up call

Trusted collaboration

Tetra Elements helped us validate our design quickly and communicate risk clearly. The report was decision-ready.

Excellent clarity in assumptions, boundary conditions, and results. The iteration cycle was efficient and professional.

Strong technical depth and communication. We appreciated the practical recommendations and next steps.

Capabilities

A focused set of simulation services—delivered with clear assumptions, validated setup, and decision-ready outputs.

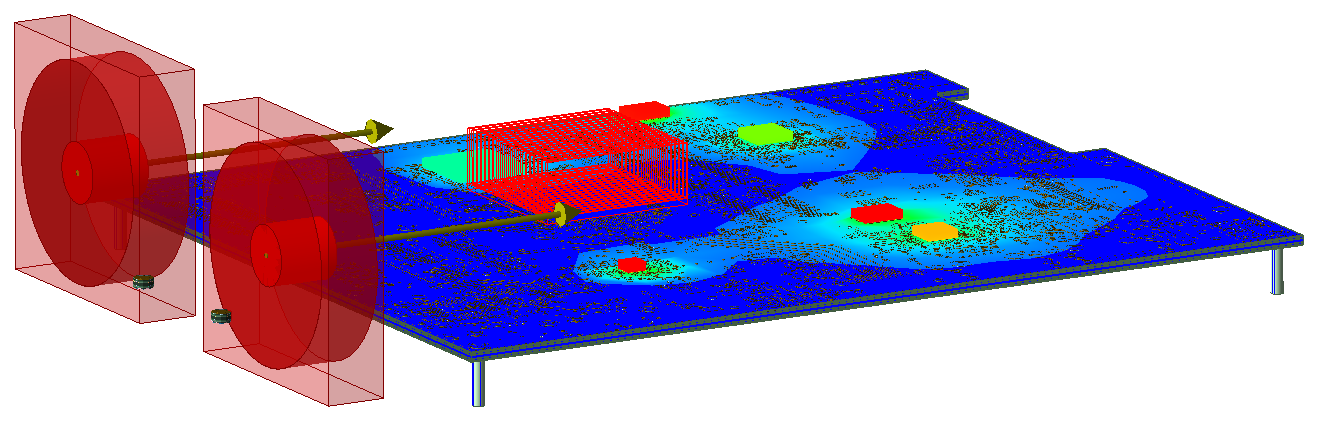

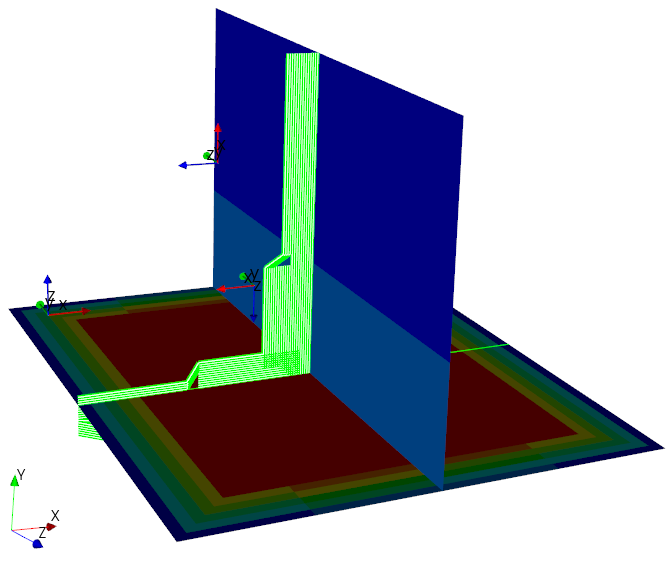

Electro-thermal simulation

- Electrical-thermal coupling

- Thermal analysis and hotspots

- Cooling mechanism evaluation

- Material and layer considerations

- Thermal reliability and stress

- Design optimization

- Boundary and environmental conditions

Carbon fiber composite

- Anisotropic material modeling

- Laminated composite behavior (ply-level)

- Interlaminar stress evaluation

- Stacking sequence effects

- Manufacturing considerations (residual stress, defects)

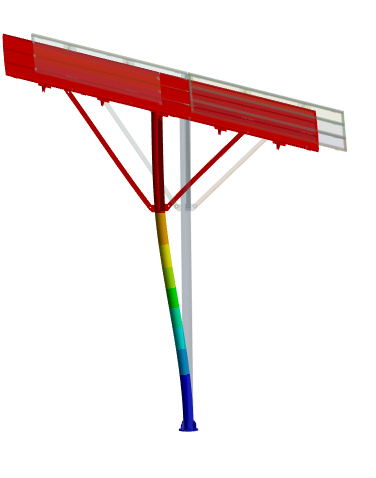

Static analysis

- Load capacity assessment

- Stress distribution

- Deformation evaluation

Dynamic analysis

- Drop tests and impact loads

- Failure modes and risk points

- Explicit dynamics

Modal analysis

- Natural frequencies

- Mode shapes

- Damping characterization

Composite structures analysis

- Material selection and constraints

- Thermal effects

- Stress evaluation

- Deployment simulation

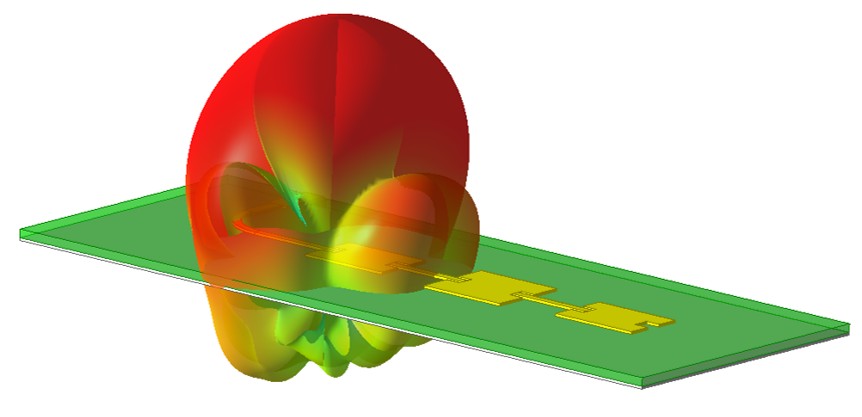

Antenna design & simulation

- Return loss (S11)

- Radiation pattern

- Gain and directivity

- Efficiency

- Impedance matching

- Near-field / far-field results

Waveguide design and simulation

- Mode analysis

- S-parameters

- Field distributions

- Power flow and loss analysis

- Efficiency metrics

Thermal analysis

- Electrical sizing of battery pack

- Heat generation and temperature distribution

- Cooling solution optimization

Optical simulation

- Nano-textured surface arrangement

- Optimal nanostructure layout

- Efficiency improvements

Fatigue analysis

- Cyclic loading and cumulative damage

- Durability and life estimation

- Stress evolution over time

Buckling analysis

- Critical load and stability analysis

- Compressive loads and failure modes

- Long-term durability assessment

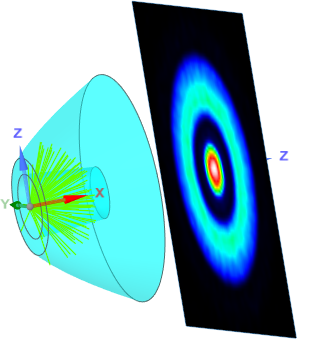

Ray tracing simulation

- Lens design

- Mirror design

- Beam propagation

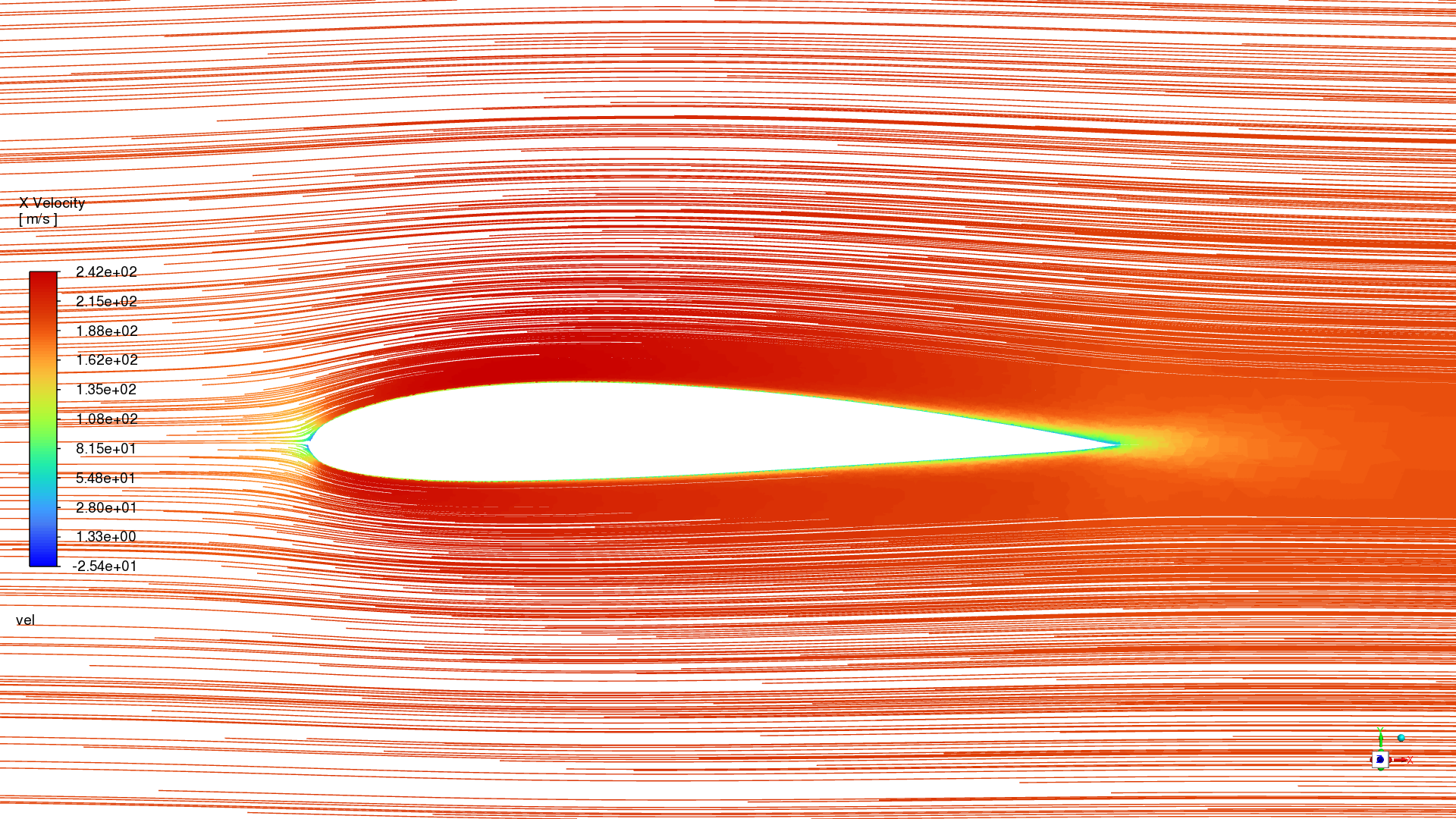

Computational fluid dynamics (CFD)

- Heat transfer

- Aerodynamics

- Fluid-structure interaction

Structural and seismic analysis

- Concrete and steel bridges and buildings

- Industrial and commercial structures

- Base-isolated and fixed-base structures

- Seismic design and analysis

- Damage estimation and validation

- ASCE, AASHTO, AISC, ASTM, FHWA, Eurocode