Temperature is not only a thermal concern — it acts like a structural load. If thermal expansion is constrained by geometry, fasteners, adhesives, or neighboring parts, it can generate stress, warpage, and misalignment.

Thermo-structural analysis couples temperature fields with structural response to predict thermal stress and distortion.

Temperature is a structural load

Materials expand when heated and contract when cooled. That movement is usually harmless if the part is free. But products are rarely free: they are bolted, bonded, packaged, sealed, stacked, or built from multiple materials. When expansion is constrained, the structure “pushes back” internally and generates stress.

Thermo-structural analysis answers: Will temperature cause deformation that breaks requirements (fit, seal, alignment), or stress that drives failure over time?

Why thermo-structural failures are often overlooked

Many teams validate thermal performance (temperatures, cooling) and mechanical performance (strength, stiffness) as two separate activities. Each can look “acceptable” in isolation—while the combined effect creates a real risk.

Common hidden failure modes

- Warping that breaks fit or causes interference

- Misalignment in precision systems and assemblies

- Thermal stress buildup in constrained joints

- Cracking / yielding from temperature gradients

- Seal leakage from differential expansion

Why this becomes expensive

- Issues appear late (EVT/DVT, qualification, field)

- Fixes require tooling/packaging redesign

- Schedule slips from repeated test cycles

- Added “patch” parts increase BOM and assembly risk

What thermo-structural analysis delivers

For decision makers, thermo-structural analysis converts temperature uncertainty into actionable design guidance: where deformation happens, where stress concentrates, and what changes reduce risk without overdesign.

Outputs you can act on

- Deformation/warpage maps vs. tolerance requirements

- Thermal stress hotspots (risk ranking)

- Interface loads for fasteners, bonds, and seals

- Design changes with tradeoffs (geometry, materials, joints)

What this improves

- Alignment retention under operating temperatures

- Reliability against crack initiation and creep drivers

- Qualification confidence and fewer late surprises

- Clearer documentation for sign-off and customers

When thermo-structural analysis is essential

You should strongly consider coupled thermal–structural analysis whenever temperature changes occur while the product is mechanically constrained or requires tight alignment.

High-value product scenarios

- Electronics with heat-generating components

- Sealed enclosures and gasketed assemblies

- Multi-material stacks (metal + plastic + adhesives)

- Precision instruments where alignment is critical

- Outdoor, automotive, aerospace thermal environments

Typical applications

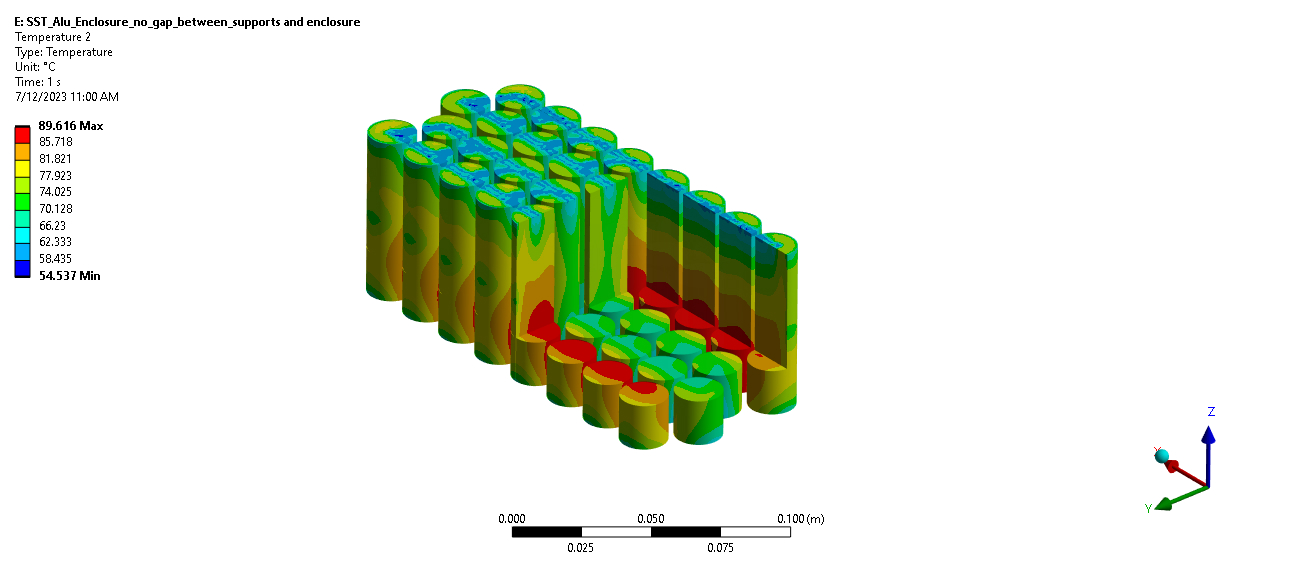

- PCB + enclosure + heat sink assemblies

- Battery modules and power electronics

- Opto-mechanical and sensor packaging

- Brackets and mounts near heat sources

- Industrial equipment with thermal gradients

Where it fits in a complete validation plan

Thermo-structural analysis complements other methods by capturing coupling effects that isolated simulations miss:

- Static analysis: Can the structure carry loads?

- Dynamic analysis: How does it respond to vibration/motion?

- Fatigue analysis: How long will it last under cycling?

- Thermo-structural analysis: How does temperature drive stress and deformation?

If you are already running thermal simulations (steady or transient), coupling them to structural analysis is often the fastest way to identify deformation and stress risks—before prototype or qualification builds.

If temperature changes happen under constraint, this analysis should not be optional.

Tetra Elements helps teams integrate coupled thermal–structural analysis early to prevent warpage, stress buildup, and qualification surprises—while keeping designs lean and manufacturable.

Note: Thermo-structural workflows typically use a thermal solution (steady or transient) as input to a structural model, capturing stress and deformation driven by temperature fields and gradients. The right approach depends on boundary conditions, material models, and how the product is constrained in real life.